Get Support

123-456-789-10

Explore AKO's cutting-edge adhesive production machines designed to meet diverse manufacturing needs:

1. Flexo Printing Machines: Achieve exceptional print quality and precision for labels and packaging with our advanced technology.

2. Slitting Machines: Enhance production efficiency with precise material cutting, suitable for various adhesive roll materials.

3. Coating Machines: Attain uniform and precise adhesive coating for self adhesive paper and more, thanks to our advanced hot melt technology.

4. Die Cutting Finishing Machines: Streamline adhesive label production with precise die-cutting and finishing for consistent quality.

AKO leads in adhesive production technology, offering innovative solutions to elevate manufacturing processes across industries.

For More AKO Selling Machineries, visit AKO Machinery.

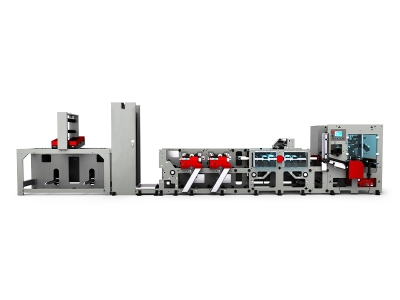

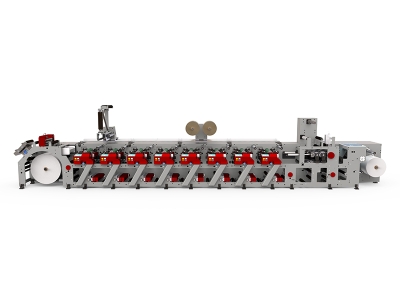

Alpha Series 420

Alpha-420 Flexo printing press is for shipping label, adhesive material, film and other materials. The whole machine adopts three servo synchronization control, uses LED UV curing, high precision and low pollution.

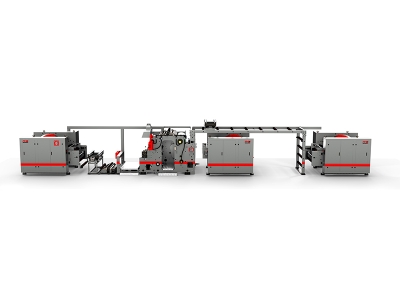

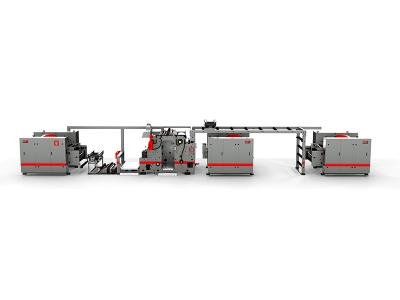

KING KONG Series 1650

Introducing the AKO King Kong 1650 Series Slitting Machine – the ultimate solution for precision and efficiency in the world of slitting technology. Experience the power of the AKO King Kong 1650 Series Slitting Machine and revolutionize your slitting process.

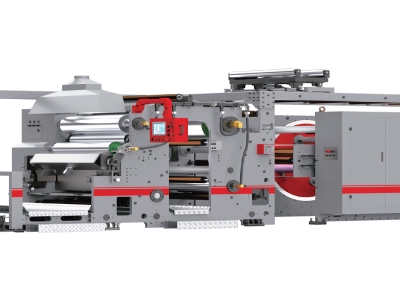

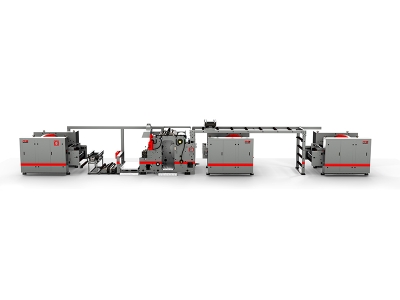

OMEGA Series 1600

OMEGA 1600 Features OMEGA compound is a hot melt coating & converting equipment to meet the needs of a variety of different applications, can be different coating amount and coating viscosity, can be full-coated and partially coated. It is mainly used in consumer labels and technical tape; Can be used on liner less paper and composite materials. The combined use of OMEGA and ALPHA silicon coating lines enables t

OMEGA Series 1300

GAMMA-1300 Features Flexibility The slit-1300 series is equipped with a high-precision automatic tool setting system. It is capable of changing the cutting width of different materials in one-key operation; unwinding configuration multiple tension control modes; slitting configuration dedusting or glue removal device. Multiple applications-PVC Films Composite material Unwinding The material te

OMEGA Series 520

OMEGA 520 Features OMEGA compound is a hot melt coating & converting equipment to meet the needs of a variety of different applications, can be different coating amount and coating viscosity, can be full-coated and partially coated. It is mainly used in consumer labels and technical tape; Can be used on liner less paper and composite materials. The combined use of OMEGA and ALPHA silicon coating lines enables the connecti

Gamma Series 1600

GAMMA-1300 Features Flexibility The slit-1600F series is equipped with a high-precision automatic tool setting system. It is capable of changing the cutting width of different materials in one-key operation; unwinding configuration multiple tension control modes; slitting configuration dedusting or glue removal device. Multiple applications-PVC Films Composite material Unwinding The material t

Gamma Series 1300

GAMMA-1300 Features DELTA 420 Flexo printing press is a kind of printing equipment which is developed by our company on the basis of absorbing foreign advanced technology experience and combining with our core technology. The press is for shipping label, adhesive material, film and other materials. The whole machine adopts three servo synchronization control, uses LED UV curing, high precision and low pollution.

Gamma Series 520

Gamma 520 Features Flexibility The Slit-520 Series optional with a high-precision automatic tool setting system. It is capable of changing the dutting width of different matereals in one-key operation; unwinding comfiguration multiple tension control modes; slitting configuration dedusting or glue removal device. All feed rollers are specislly treated with a anti-sticking coating; Winding with sliding type air s

Delta Series 520

DELTA 520 Flexo printing press is a kind of printing equipment which is developed by our company on the basis of absorbing foreign advanced technology experience and combining with our core technology. The press is for shipping label, adhesive material, film and other materials. The whole machine adopts three servo synchronization control, uses LED UV curing, high precision and low pollution.